Solid-Hull Models Present a Challenge: Finding a Large Enough Block of Wood

Bread-and-Butter Solid Hull Construction Makes Scratch-Building Easier

Cutting Planks to Ship Plan Waterlines Shortens Hull Shaping Time

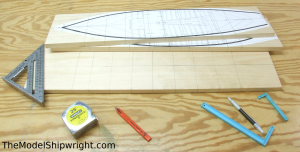

One of the most popular methods of scratch-building a solid hull for larger ship models, called the bread-and-butter technique, reduces the thickness (and expense) of wood needed as compared to the solid block method.

This method uses the waterlines from the ship plan to cut out several planks that will be layered like slices of bread to create the solid hull, and glued together (the butter).

A major advantage of this method – in addition to less cost for wood than a solid block – is that since each plank is cut to the breadth of the hull at a certain level, there is less filing and sanding to reach the final shape than a single block of wood, which must be cut to the widest breadth of the hull.

We are launching a project Building a Bread-and-Butter Solid Hull Ship Model to show step-by-step how it’s done.

Books Available From The Model Shipwright

Souvenirs de Marine by

François-Edmond Pâris