Evolution of the Modern Cargo Ship

The history of the SS Keystone State née SS President Harrison shows, in one vessel, the dramatic transition of styles in cargo vessels during the 20th Century.

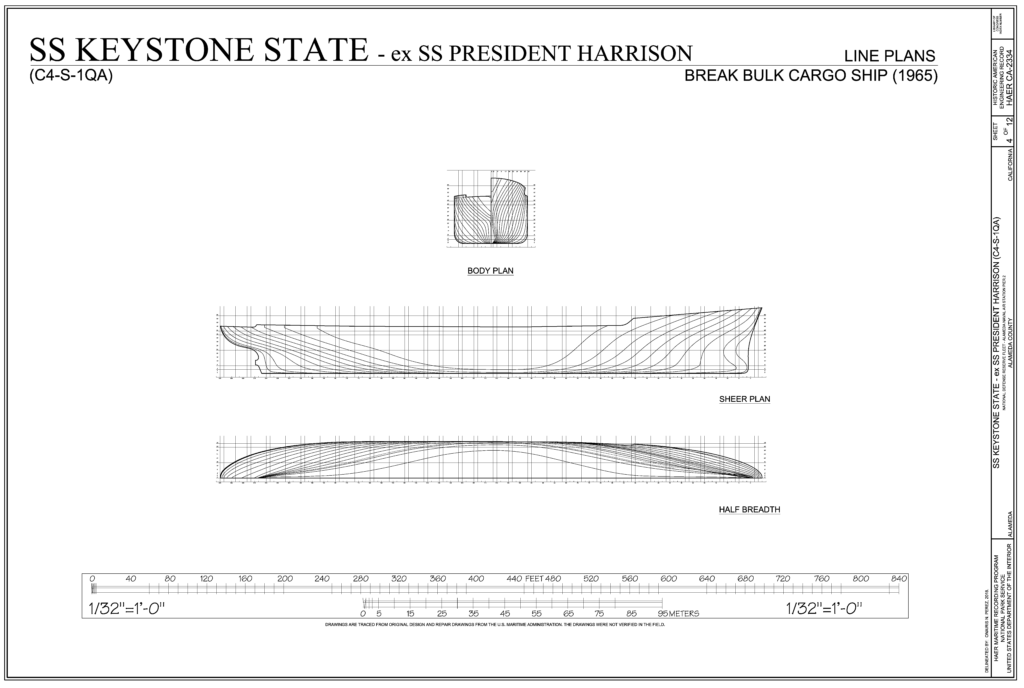

In 1965 the National Steel and Shipbuilding Company of San Diego, California laid the keel for the break-bulk cargo vessel SS President Harrison – later SS Keystone State. She and her sisters, SS President Polk and SS President Monroe, were built for the American President Lines of San Diego, California. The vessels were designed to the Maritime Administration (MARAD) Master Mariner C4-S-1qa class, an evolution of the Mariner class, which was developed in the 1950s.1

Break-bulk cargo ship design fell between bulk carriers, used to haul loose cargoes such as grain, coal, oil, or iron ore, and modern intermodal or “ISO” container carriers, which were introduced a decade prior to SS President Harrison’s construction, but not at the time as widely adopted as they are now.2 In fact, American President Lines had previously constructed two “Sea Racers,” of the MARAD designation C4-S-1q that were purpose built to exclusively transport 20-foot ISO shipping containers. While the company decided to go back to break-bulk cargo handling with President Harrison and its sister ships, the new design also included space suitable for container transport. The “a” added to the end of the class designation showed the design lineage to the Sea Racers and Mariners that came before them.3

If you are still trying to visualize exactly what “break-bulk cargo” is, think back to old movies that show a dockside scene where stevedores wrestle a net full of wooden boxes being raised by a cargo boom toward a ship’s open deck hatches. That is the essence of break-bulk cargo.

The break-bulk logistical chain begins with a company sending a truckload of its product to a dockside warehouse, where it would be unloaded to wait for a ship. Once the ship arrived, the product would be moved dockside, where cargo booms on the ship would lift it into its cargo hold. This process might be repeated at a number of wharves in several cities, until the ship’s holds were full, and it would depart for its first delivery destination.

Then the process was repeated in reverse as the ship was unloaded, and the cargo warehoused, and then transported to market. The obvious downside to this method is the number of times the cargo must be handled, which increases the cost of shipping. But it did have an upside: A company could ship its products in smaller quantities than allowed for by the modern ISO containers, which are 20 to 40 feet in length. And, since the ship carries its own loading tackle, it can loaded and unloaded at smaller port facilities that lack massive container cranes.

Break-bulk shipping continues to this day, although today loads are palletized and plastic film-wrapped. It is often utilized for shipments from major ports to smaller ones, and for products too large to fit into a shipping container, such as large industrial equipment. While it still entails more handling, It avoids the cost shipping of empty containers, an eventuality caused by the nature of some ports shipping out less product than they receive.

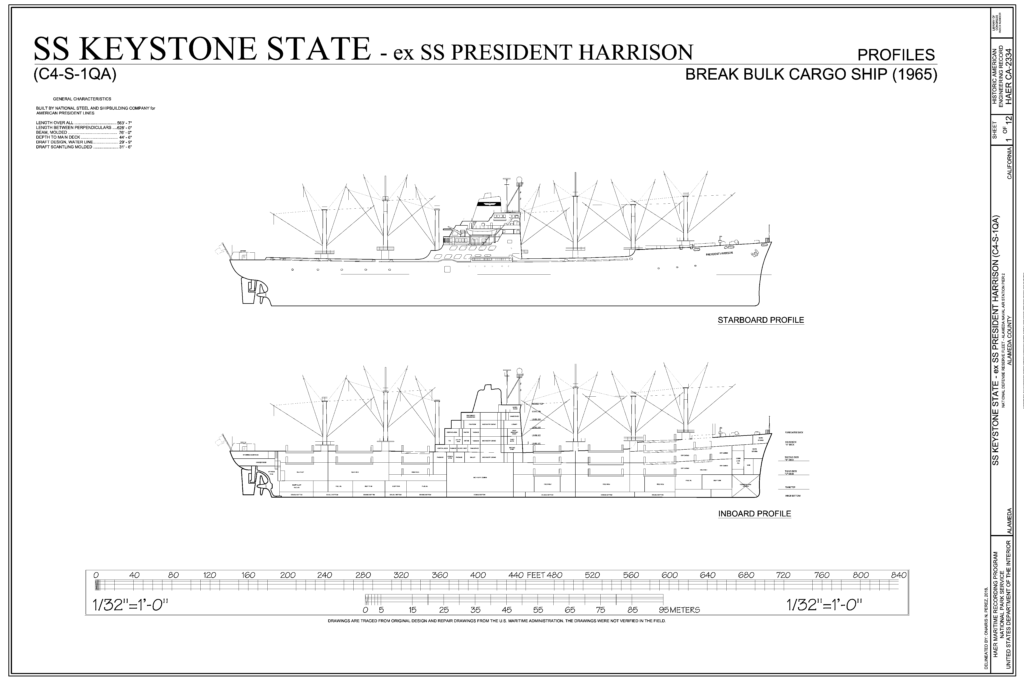

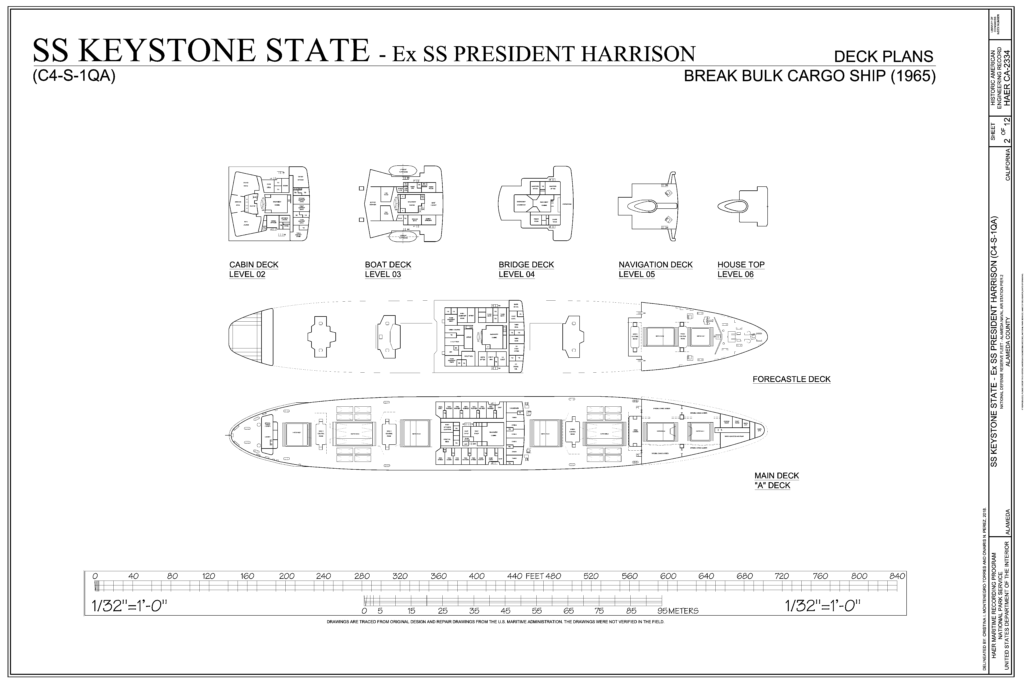

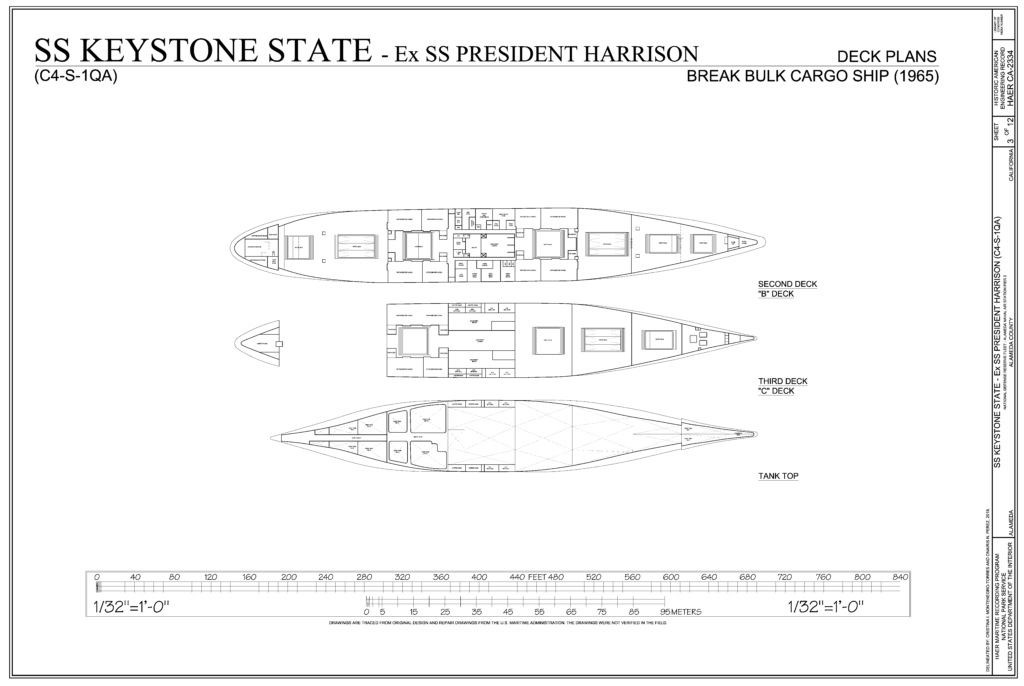

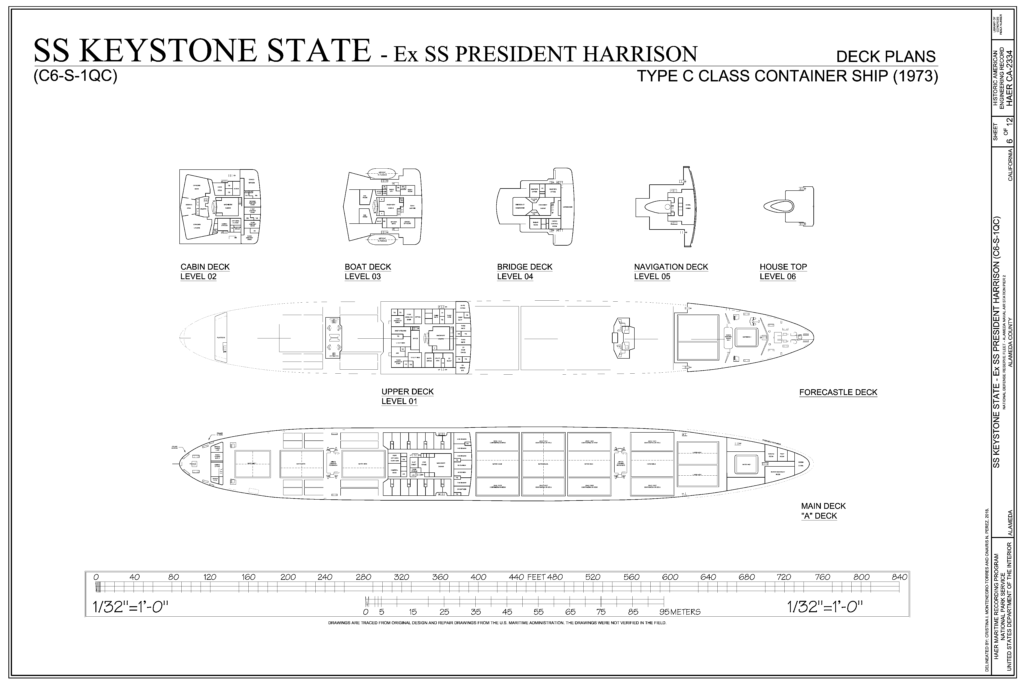

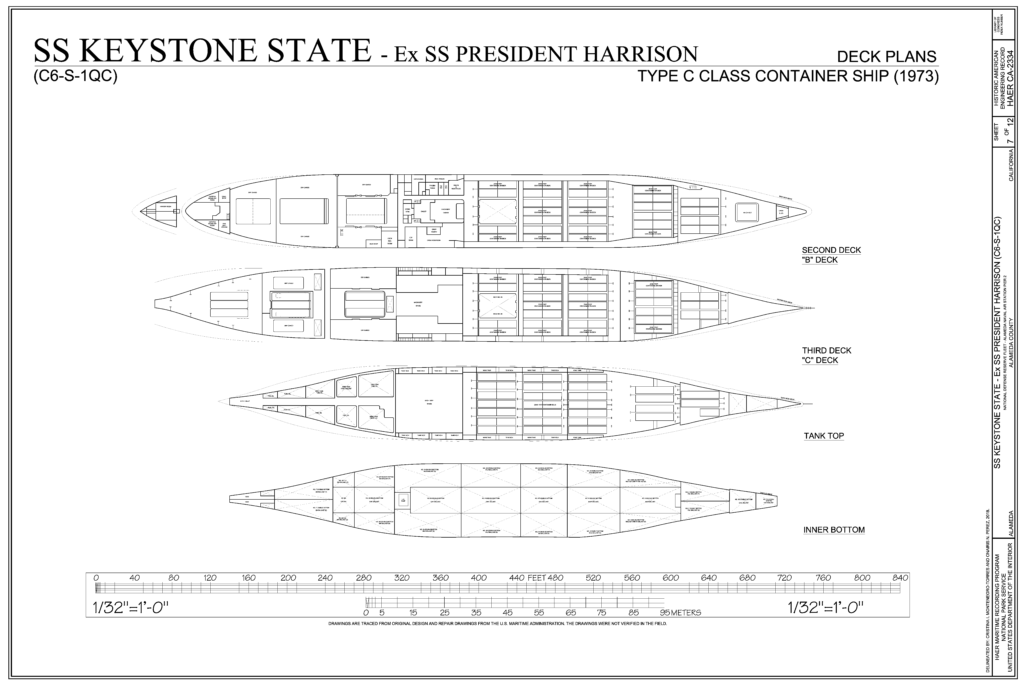

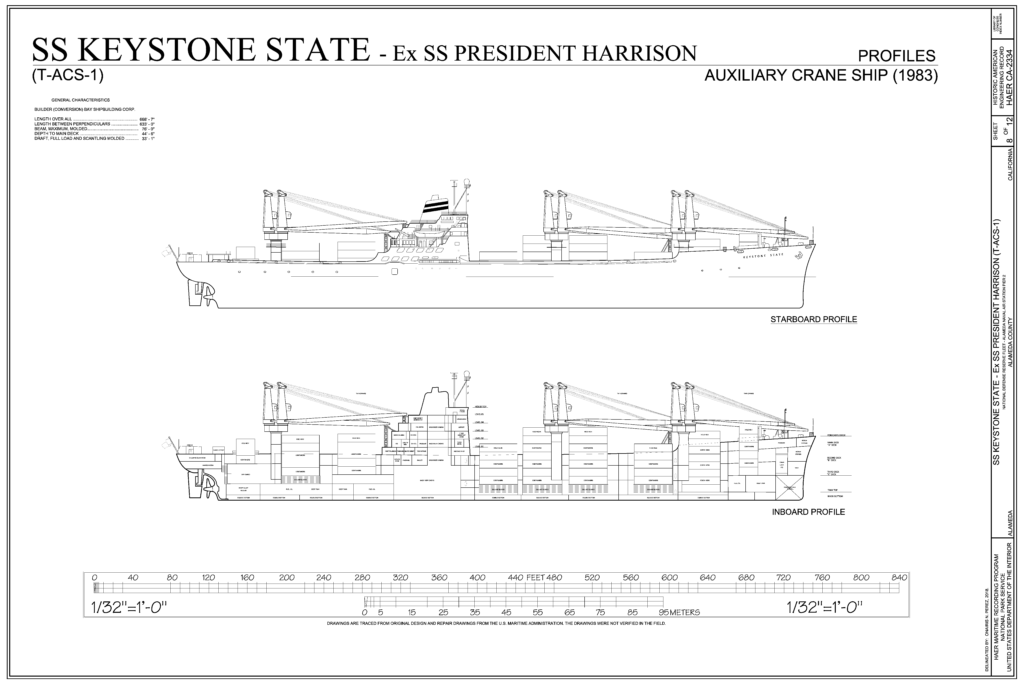

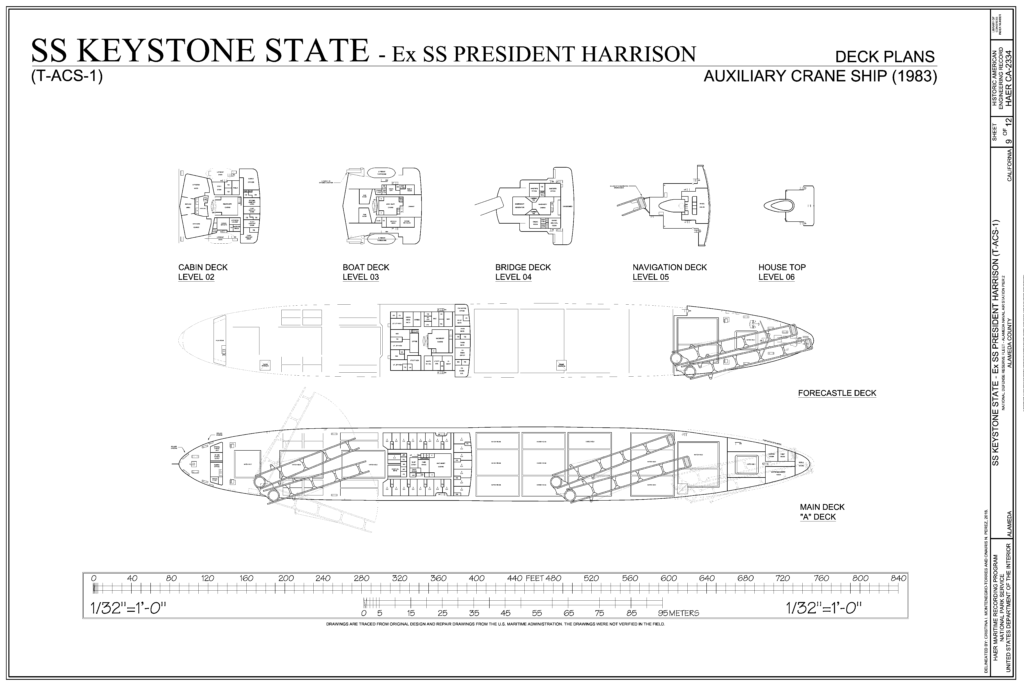

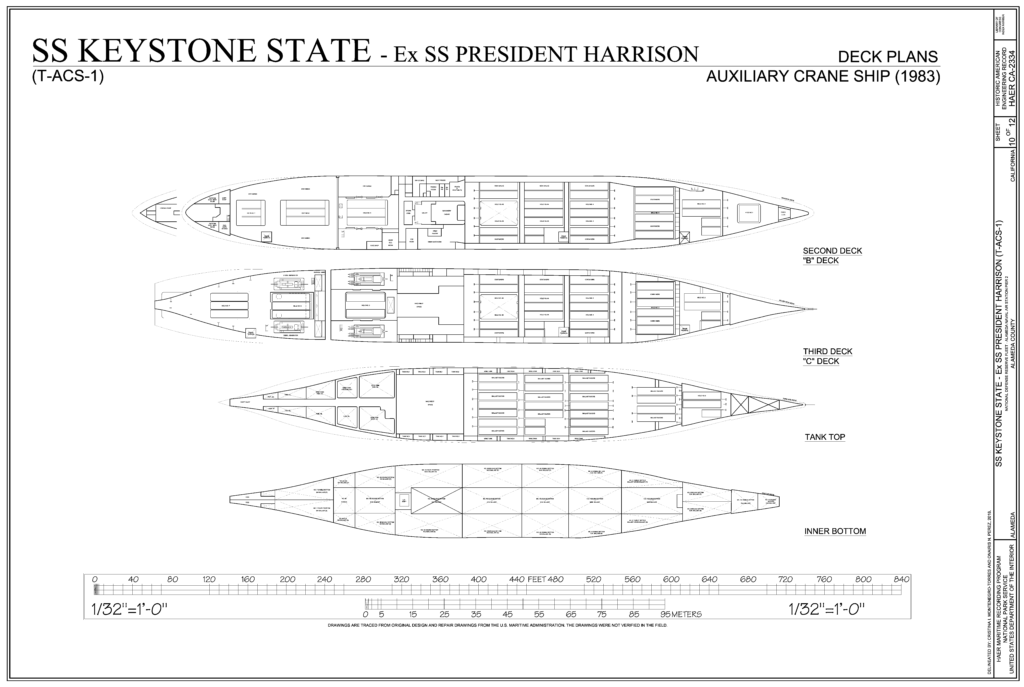

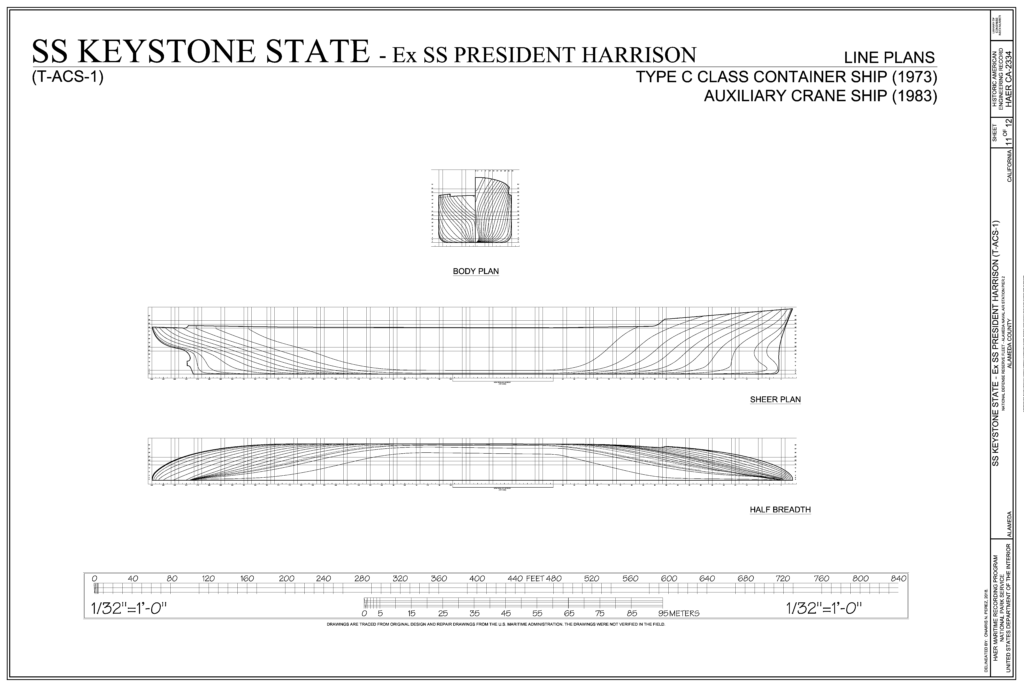

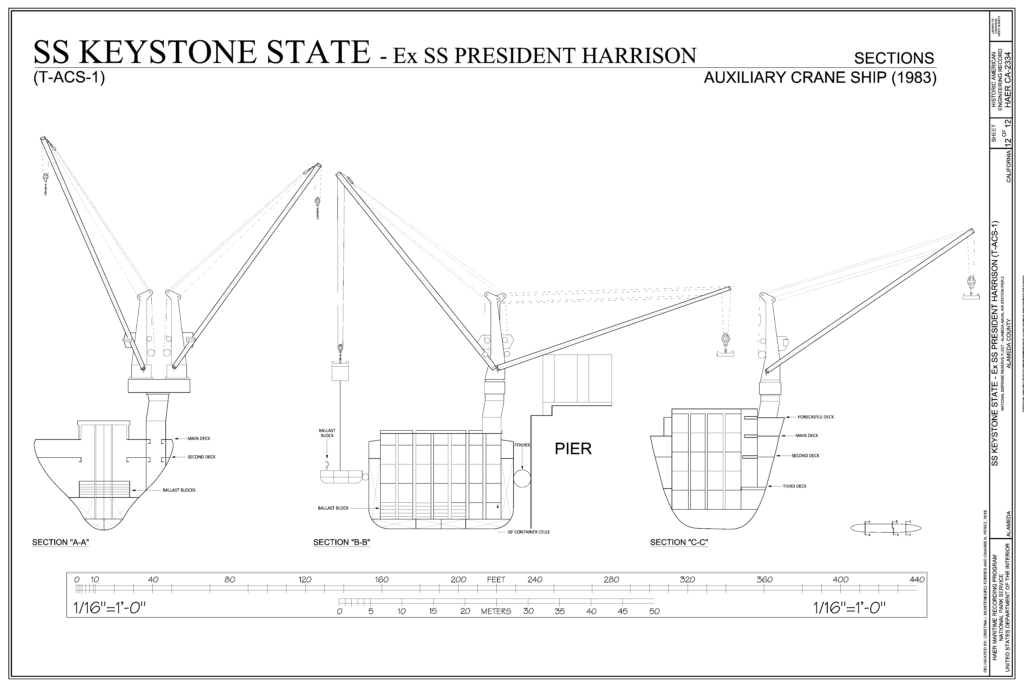

SS President Harrison’s 563-foot, seven-inch length was divided into seven holds accessed by main deck hatches with four decks below, offering space for dry, refrigerated, and liquid cargoes. Cargo was loaded via booms on five pairs of kingposts. The cargo booms and tackle were altered from the Mariner class design to also handle shipping containers. The foc’s’le deck was extended on the Master Mariner class to include the hatch for hold 2, and the first winch house was relocated to the foc’s’le deck from the main deck. Holds 1 and 2 were also given a centerline bulkhead for bulk grain transport. The superstructure, located slightly astern of amidships, had five decks with space to house a crew of 45 plus two cadets and 12 passengers in eight staterooms.4

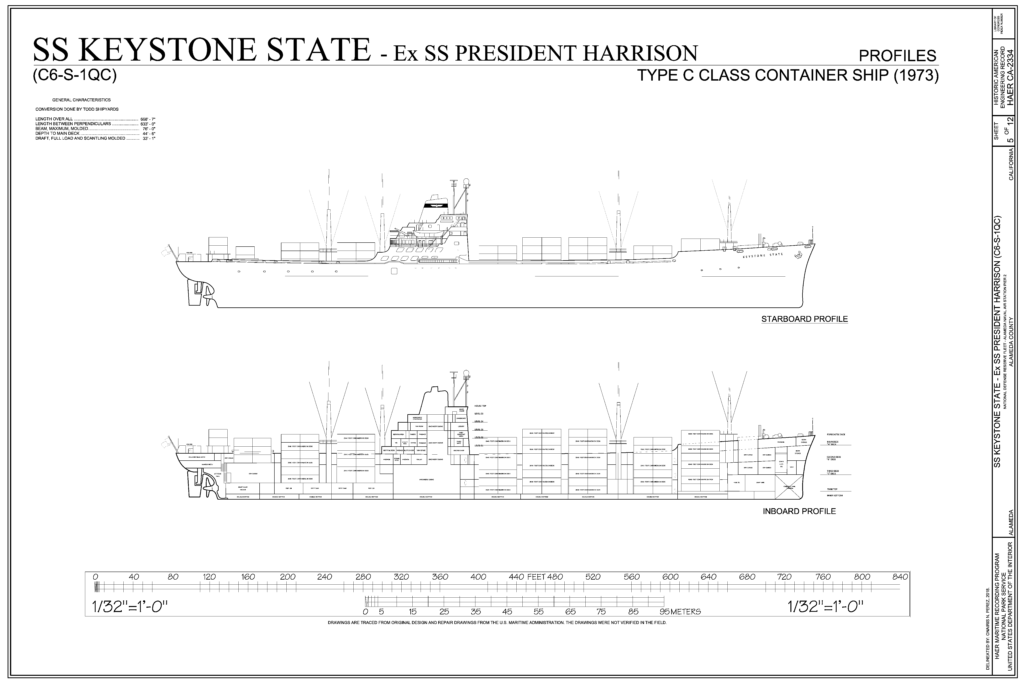

In 1973 Todd Shipyards converted the President Harrison to the Maritime Administration’s Master Mariner class C6-S-1QC. This required lengthening the hull by 105 feet, adding two holds, and converting the existing break-bulk holds to carry ISO shipping containers.

In April, 1980 Daily Shipping News announced that the SS President Harrison was completing its 100th voyage on the company’s Taiwan to Manila route. At that point it had completed more voyages than any of the company’s other 22 ships. American President Lines operated the ship through 1982, when they transferred the ship over to MARAD. The ship then joined the National Defense Reserve Fleet in Suisun Bay, California.

The Chief of Naval Operations chose President Harrison and its two sister ships President Polk and President Monroe to be the first vessels for conversion to Auxiliary Crane Ships, MARAD design C6-S-MA1qd, military designation T-ACS. The design changes were to make the ships capable of loading and off-loading container ships that no longer carried self-loading equipment – a more common occurrence as shippers had begun to depend on port facilities to have cranes to load and unload containers.

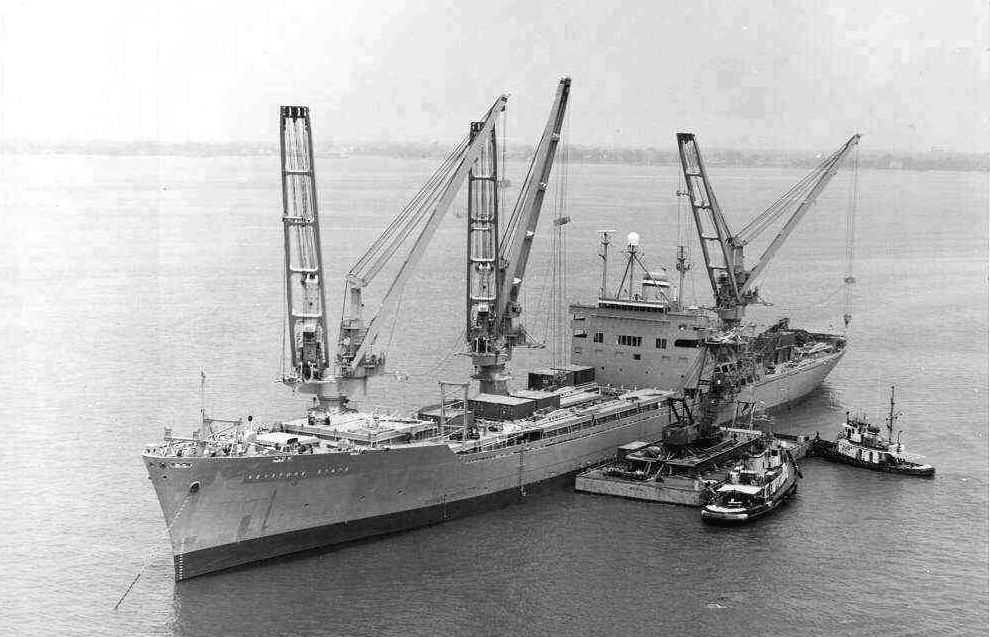

Bay Shipbuilding Corporation of Sturgeon Bay, Wisconsin removed the kingpost/boom gear and replaced it with three twin-boom rotating deck cranes on the starboard side. This also required modification of hatch covers and container cells that were in the way of the cranes. The ballast configuration also had to be adjusted to compensate for the weight of the cranes and provide stability during extreme cargo lifts. Diesel generators were also installed to power the cranes. The wheelhouse was moved up one level in the superstructure because, fully loaded, the shipping containers obscured the view from the original bridge. Passenger staterooms were converted to crew quarters. In 1984 the vessel was renamed SS Keystone State, and delivered to the U.S. Navy. Its sister ships were rechristened SS Gem State and SS Grand Canyon State.

In September 1984 SS Keystone State participated in a Joint Logistics Over the Shore training exercise to demonstrate the capabilities of an auxiliary crane ship. These missions feature sealift operations in regions with inadequate port facilities, to aid U.S. military and humanitarian efforts around the world.

SS Keystone State remains in the Ready Reserve Force in Alameda, California, and can be ready for service within five days.

FOOTNOTES

1. Hale, Westley, Historic American Engineering Record CA-2334 https://tile.loc.gov/storage-services/master/pnp/habshaer/ca/ca4300/ca4313/data/ca4313data.pdf pp3

2. Levinson, Marc, The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger, 2nd edition, 2016 pp. 64–69.

3. Hale, Westley, Historic American Engineering Record CA-2334 https://tile.loc.gov/storage-services/master/pnp/habshaer/ca/ca4300/ca4313/data/ca4313data.pdf pp 7

4. Hale, Westley, Historic American Engineering Record CA-2334 https://tile.loc.gov/storage-services/master/pnp/habshaer/ca/ca4300/ca4313/data/ca4313data.pdf pp3-5, 7 Note: all further data comes from this report, unless footnoted differently.

5. https://vesselhistory.marad.dot.gov/ShipHistory/Detail/2875

6. Perez, Onairis N., delineator, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

7. Montenegro-Torres, Cristina I.,Perez, Onairis N., delineators, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

8. Montenegro-Torres, Cristina I.,Perez, Onairis N., delineators, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

9. Perez, Onairis N., delineator, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

10. Perez, Onairis N., delineator, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

11. Montenegro-Torres, Cristina I.,Perez, Onairis N., delineators, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

12. Montenegro-Torres, Cristina I.,Perez, Onairis N., delineators, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

13. Perez, Onairis N., delineator, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

14. Montenegro-Torres, Cristina I.,Perez, Onairis N., delineators, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

15. Montenegro-Torres, Cristina I.,Perez, Onairis N., delineators, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

16. Perez, Onairis N., delineator, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/

17. Montenegro-Torres, Cristina I.,Perez, Onairis N., delineators, Historic American Engineering Record CA-2334, 2018 https://www.loc.gov/item/ca4313/