Sona Professional Jeweler’s Saw with 144 Assorted Saw Blades

Part Number: 81973SB2

Specs:

Saw Frame:

- Steel frame

- Frame length: 7-½”

- Depth of cut: up to 3”

- Wooden handle, size: 4” x 1”

- Adjustable frame to hold various blade lengths

- Thumbscrews to firmly secure blades into the frame

144 Piece Saw Blade Set

- Steel Blades

- 24 each of sizes: 2, 1, 1/0, 2/0, 3/0, 4/0

- Teeth per inch:- 43, 51, 53, 56, 61, 66

We have a lot of tools available to us that are useful in model shipbuilding. When it comes to cutting or material removal handy tools that most people would think of include knives, chisels, rasps, files, and sandpaper. One a lot of people may not think of at first for such delicate work: saws.

But, just as our other hobby tools are miniature versions of larger tools, there are saws sized to work the small materials we use in model ship building.

Now, an old ship modeler I knew used to say “saws are for people that don’t have patience.” I always took that with large grain of salt, as I’m pretty sure he used them for certain jobs when building. But, it can also be seen as a warning that, as with their full-size partners, mini saws make it easier to get into trouble and remove too much material than the other woodworking tools I’ve noted earlier.

When it comes to saws, there are several kinds that come in handy. A mini miter saw, often referred to as a “razor saw,” works great for straight cuts of strip material. They come with a handle as a single disposable unit, or as a blade that fits into a hobby knife handle. You can even get miniature miter boxes to insure accuracy of your cuts. The three main brands of these tools we recommend are Xacto, Zona, and Excel.

Xacto, Zona, and Excel razor saws on:

Amazon: https://amzn.to/3MuRK73

eBay: https://ebay.us/FHg71h

Xacto, Zona and Excel miter boxes on:

Amazon: https://amzn.to/3G20S0K

eBay: https://ebay.us/52Q1J2

NOTE: If you purchase from the links on this page, this channel may earn a commission.

But when you need to cut a curved shape you need a thinner blade. That’s where a frame saw or bow saw comes in handy. It is a saw that has a frame that supports the blade so it can be thinner and lighter for more delicate cuts. Coping saws are the most common frame saw you will see in hardware stores. It is used like a hand-held scroll saw, often for cutting moldings in home construction.

Coping saws on:

Amazon: https://amzn.to/3yOcT8l

eBay: https://ebay.us/i6KPYy

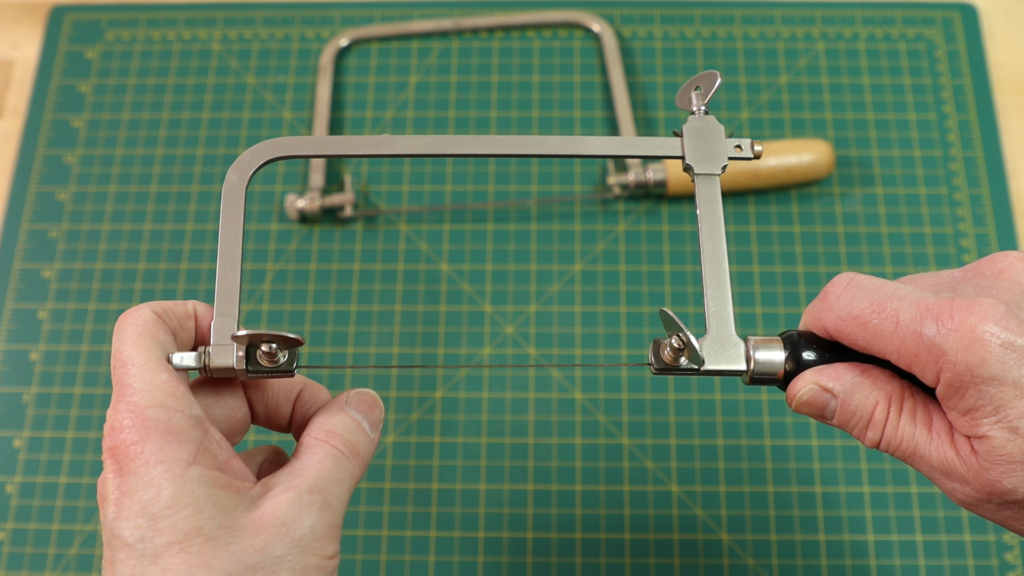

An even smaller version of the frame saw is a jeweler’s saw. This one is available from Model Expo, and has an adjustable frame for use with different length blades, with a maximum size of seven and one half inches.

Model Expo (Model Shipways) on:

eBay: https://ebay.us/kRUmR2

Amazon: https://amzn.to/3CBrROV

It comes with 144 blades: 24 each of sizes 2, 1, 1/0, 2/0, 3/0 and 4/0. They can be used to cut metal as well as wood and plastic.

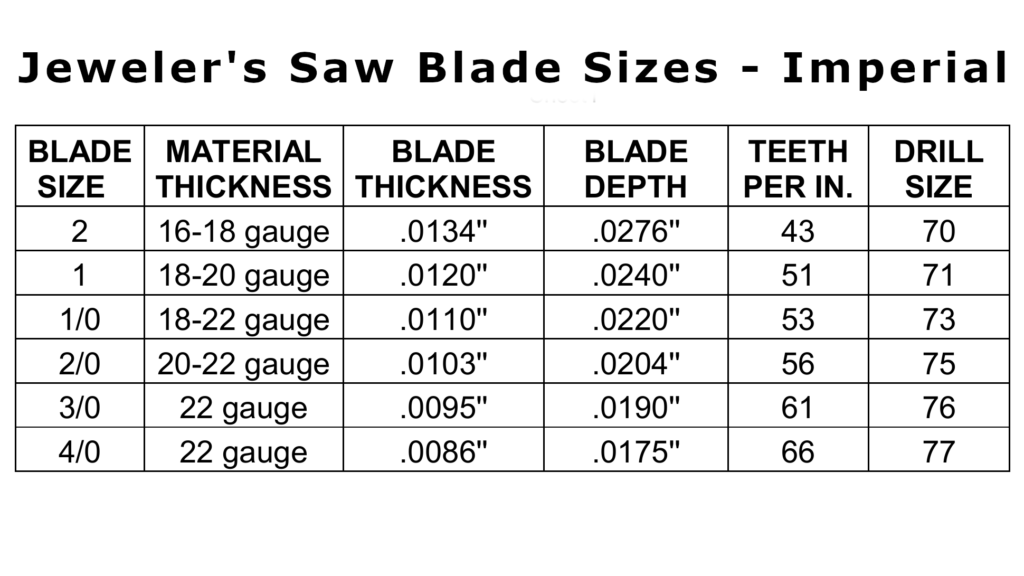

Here’s a chart showing the dimensions of the various size blades:

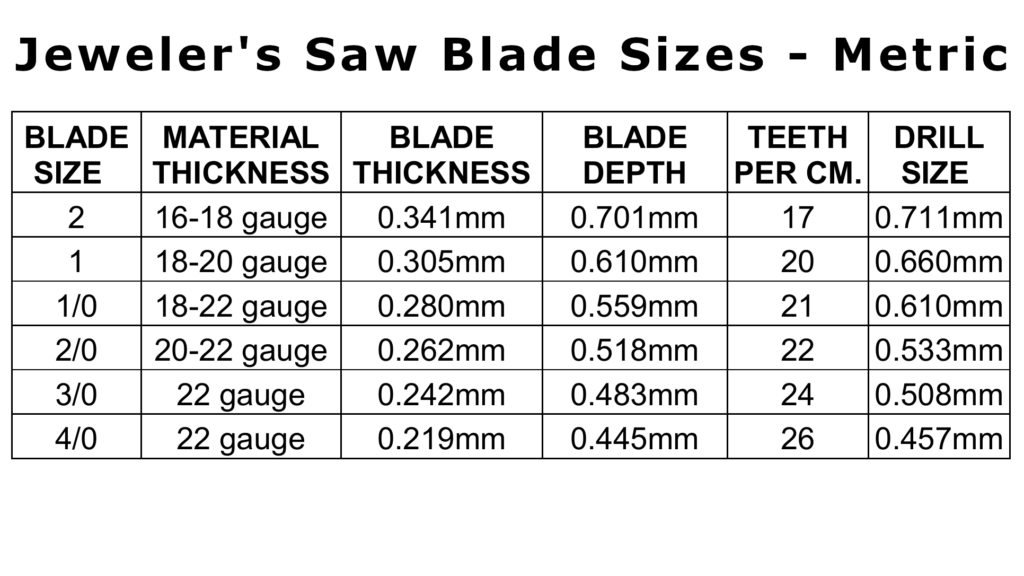

Here’s a chart showing the dimensions in metric units:

The drill size in the last column is the size of drill bit needed to fit the blade when doing an interior cut. Interior cuts are major advantage of coping and jeweler’s saws: you can cut inside a piece without starting at the edge. Simply detach one end of the blade, thread it through an opening within the work piece, and reattach the blade to the frame. The last column in the chart shows the minimum drill bit size for each blade if using the saw in this way. When using this method, this saw can cut to a depth of three inches from the edge of the piece, so depending on the total size, you may have to do this from multiple sides to reach all of the cut. Model Expo also has micro drill bits in the sizes on the chart.

Xacto, Excel, and Zona jeweler’s saws on:

Amazon: https://amzn.to/3LwXITE

eBay: https://ebay.us/SMjOz4

I’m using these old router-cut frames as an example, but this saw is really designed for cutting much smaller shapes, especially from sheet metal. There are plenty of videos showing how to do just that on jewelry making channels on YouTube.For these pieces interior cutting is not really necessary, you can just cut through the waste wood around the piece to get to the interior. I prefer doing the interior cut to keep the waste wood in one piece in case I need a weird shaped piece of wood later. It also makes it easier to trace the outline of the piece you removed, in case you need to replicate a broken or damaged part.

Note that I have the saws set with the teeth pointing down so it cuts on the downstroke. It’s much easier to control the cut while pulling, which puts pressure to the frame to keep the blade tight than pushing, which pulls the end of the frame, potentially reducing the tension that holds the blade taut.

A word on installing the blades: unlike the coping saw that has pins in the end of the blades to help hold the blade in place while tightening the frame, the jeweler’s saw has plain blades that are held in place only by tightening the wing bolts on the mounting pads. What I’ve found best is to loosen the bolt that holds the frame to size, Install the blade, and then tighten the frame by pushing on the bottom end before again tightening the frame bolt.

Now I just need to find a project that calls for cutting sheet metal into odd shapes.